Natural Gas Pipe Line

Sizing Chart

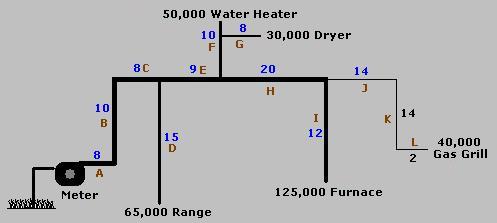

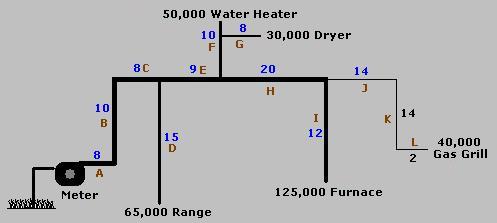

Example of a pipe system for a residential home

Make sure the gas line can

handle your generator

To add a generator

to a gas system you have to make sure you do not "starve" the other

appliances. Often, the sizes can be modified for emergency use.

In other words, a gas line that you would normally not connect a generator to you

just may

decide to you can because in the event of an emergency, you will not be using

the gas grill or the gas dryer so the BTU loads of those appliances can be

eliminated from your calculations.

Normally, correct pipe size is important so

that each gas appliance has enough natural gas to function correctly.

To verify that you have a correctly sized system you should first read each

data plate on the equipment that is connected to the system. Each is

rated in maximum BTU required.

If the plates are not available or you just

want a good estimate use the appliance chart at the bottom of this page to

estimate average appliance BTU load.

There is a more exact formula but you can

round off the conversion of CF to BTU by using 1=1000 (for example: 174 CF

on the chart would be equal to 174,000 BTU). This will give a more

conservative total estimate. Also use 10 CFH per horsepower of engine

at full load. So a 10 hp engine would be 100 CFH at full load.

Even if used at 1/2 load on average the pipe must be sized to handle the

full speed of the engine.

What size hook-up hose

at the generator is needed?

If the hook-up hose is kept to 6' or less,

the use of a 1/2" hook-up hose and quick disconnect coupler for up to 18hp

engines is acceptable. The point is to have the correct size pipe up

to the shut off valve for the generator. It is like would be necessary

if using an electrical appliance on a very long extension cord. The

extension cord may be quite large but the wire on the appliance may be quite

a bit smaller. The same principles apply. Having a sufficient

amount of gas at the shut off and QDC to feed the generator is the key.

What size Pipe can your

generator connect to in the drawing above?

What has to be done is to reverse engineer the

pipe system Write down the pipe sizes and the BTU load of each branch

of the gas system.

For example let's use

the pipe layout above:

BTU Load of the range is 65 CFH

BTU Load of the water heater is 50 CFH

BTU Load of the dryer is 30 CFH

BTU Load of the furnace is 125 CFH

BTU Load of the grill is 40 CFH

Total CFH load is 310

The length of pipe from the gas meter to the farthest appliance (which is

the grill) is:

(A,B,C,E,H,J,K,L OR 8+10+8+9+20+14+14+2) 85 feet.

There are no 5' steps in the length chart so you have to go to the next

higher column which is 90 feet. Once the longest run is determined, you

must stay in that column for all other appliances.

Using the next higher column labeled 90 feet

on the pipe chart, we will enlarge that section and eliminate all the

others for clarity to show the CFH and pipe size

needed:

|

Pipe Size |

90' |

| 1/2 |

53 |

| 3/4 |

111 |

| 1 |

208 |

| 1-1/4 |

428 |

| 1-1/2 |

641 |

| 2 |

1234 |

| 2-1/2 |

1968 |

| 3 |

3476 |

Pipe A, B and C should be 1-1/4" (there

is no 310 on the chart so you must go to the next highest number)

Pipe D to the range should be 3/4".

Pipe E trunk line should be 1-1/4"

Pipe F to the water heater and dryer

should be 3/4"

Pipe G to the Dryer should be 1/2"

Pipe H trunk line should be 1"

Pipe I to the furnace should be 1"

Pipe J, K, and L to the grill should be

1/2"

So as you can see adding a 10hp 100 CFH

load to the system is difficult. For instance the grill line can

accept only 13 CFH more which equates to a 1.3hp engine. But if

you did not use the grill while operating the generator, you can connect

a 5.3hp engine to the pipe. The furnace

line was on the border of the next size smaller so it can accept (208 -

125 = 83) another 83 CFH or an 8.3hp engine.

But remember the main truck line can

handle up to 428 CFH and at this time only 310 is connect which leaves

an additional 118 CFH or a 11.8hp engine can be connected to the system

at A, B, C, or E unless the plumber installed 1-1/4" all the way which

they will do sometimes to eliminate reducer fitting, etc. The use

of line F would also be good if the dryer and water heater is not

operated at the same time. This line can hand up to an 11.1hp engine.

Now you understand why we can not

answer piping questions over the phone. If you want to trace out

your system and mark all the loads and pipe sizes and request a review to

see if your generator can be connected at a certain point we would be

glad to do that for free. You can fax it to 304-872-3359 24 hours

a day.

Note: Any nipple or other piece that is

smaller in the system and then goes larger again is to be rated from the

reduced piece onward. For instance, if a 1 inch pipe runs

30' then drops to 1/2" for 6" and then someone installed 3/4" pipe and

ran an additional 40 feet, the 40 feet of 3/4" pipe would all be

considered 1/2". You will never get more gas through the 3/4" pipe

than will pass thorough the 1/2" nipple.

Pipe

Size Chart